How to Choose LDPE vs. LLDPE Stretch Film?

Release time: 2025-07-21

In the industrial packaging field, the selection of PE stretch film?directly impacts transportation safety and cost-effectiveness. As a technical expert with 19 years of experience in packaging materials, Hefei Lihe Packaging breaks down the essential differences between two major materials based on molecular structure and application scenarios:

Material Property Differences

LDPE (Low-Density Polyethylene) With highly branched molecular chains, LDPE offers excellent transparency and high gloss. The soft nature of LDPE allows the film to have high extensibility, giving it a smooth feel when manually wrapped, but its puncture resistance is relatively weak. It is like high-transparency crystal-beautiful yet needs careful handling.

LLDPE (Linear Low-Density Polyethylene) LLDPE has a regular linear molecular structure, with copolymer monomers enhancing the intermolecular forces. Test data shows that LLDPE films?have over three times the puncture resistance of LDPE, and their elongation rate increases by 50%. They are less likely to break when stretched at high speeds on automatic wrapping machines, making them the safety guard for pallet or heavy item packaging.

Lihe Packaging’s Intelligent Manufacturing Solutions

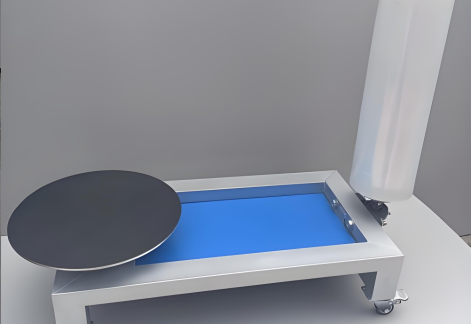

Relying on our self-optimized composite film production lines, we achieve precise control over material performance:

- By precisely controlling temperature, we achieve a crystallinity of over 65%, producing high-transparency films?with a haze of less than 5%, perfectly suited for display packaging such as luxury goods and electronics.

- Using blending modification technology, we maintain a 200% pre-stretch rate while improving puncture resistance to the industry-standard 130%. Paired with fully automated production lines, we ensure “zero-damage” packaging for automotive parts.

Industry Application Data Comparison

| Indicator | LDPE Stretch Film | LLDPE Stretch Film |

| Typical Application Scenarios | Daily consumer goods/light e-commerce items | Mechanical parts/metal products |

| Film Thickness (μm) | 15-20 | 17-23 |

| Unit Packaging Cost | Low (low film consumption) | Even lower (high strength reduces consumption) |

Sustainable Packaging Practices

Lihe Packaging strictly adheres to REACH regulations, ensuring that films are 100% recyclable with virgin material production. Our IoT quality monitoring system ensures a defect rate of≤0.8%, reducing waste film by over 150 tons annually-equivalent to the plastic consumption of 400,000 courier packages.

Choosing a reliable PE stretch film manufacturer?is like selecting a safeguard for secure transportation. Through CNC-controlled precision adjustment of molecular orientation, Lihe ensures that LLDPE films remain intact under the impact of 15kg angular cargo. In today’s ongoing packaging cost optimization, Lihe Packaging, supported by the ISO 9001/14001 dual certification system, provides a full-chain solution from material selection, structural design to intelligent manufacturing for global clients.